Presented below are two pages from the original Second World War memoir, but translated to English.

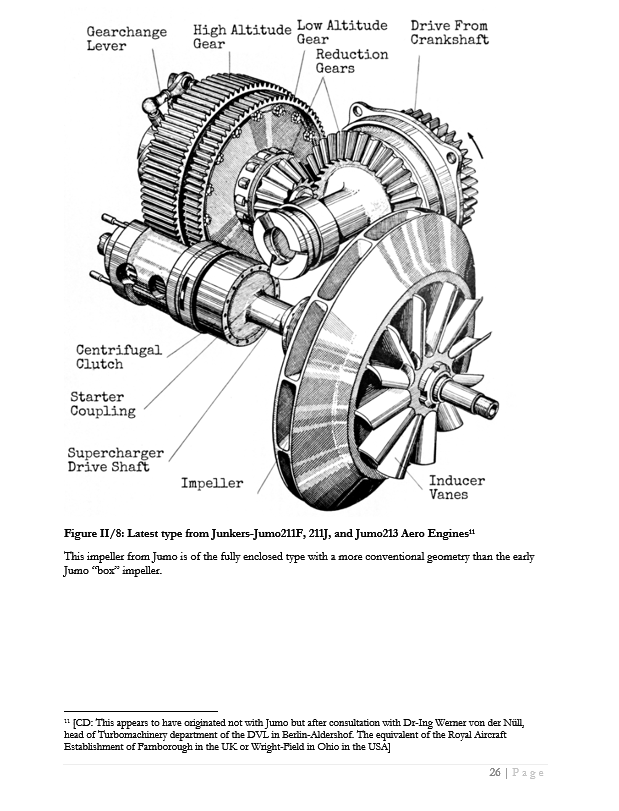

The first page shows the effect of different compressor blade geometries, using an early Turbojet engine compressor by Heinkel/Hirth as an example. This was unusual as it included what would now be called “mixed flow” blade shapes, which are essentially half way between axial and radial.

Here Dr.-Ing. Kollmann describes the different effects these have on the compressor characteristic shape, essentially the mixed flow stage is useful as it flattens the curve of the complete compressor, considerably more than would be the case were only axial stages used, this means the compressor has a considerably wider useful operating range than a pure axial compressor.

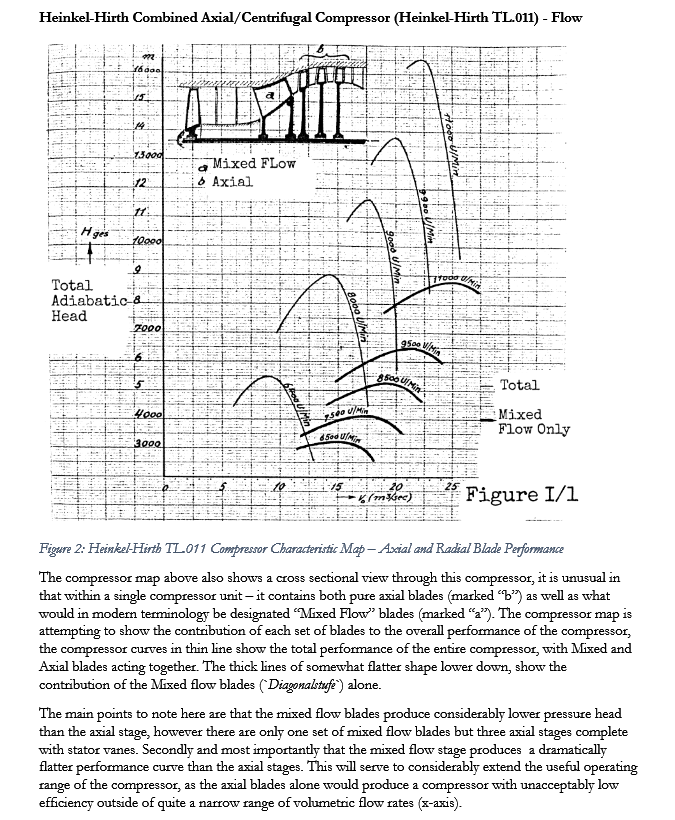

Another area where a lot of work was carried out was in blade vibration, as later in the war, centrifual stages with blade tip speeds of 500m/s were experimented with, to increase high altitude performance of existing compressors. This created a lot of vibration failures, and Kollmann describes various practical tests which were carried out and sucessful shapes to reduce blade vibrations.

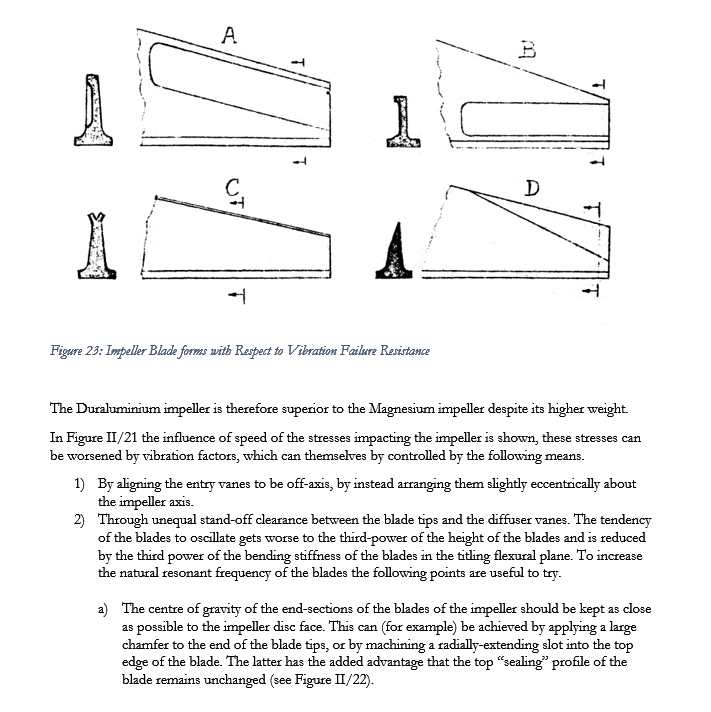

Below is a section of a very early impeller by Junkers, which was quickly shown to be of poor performance. Junkers enlisted the help of compressor experts to design a revised impeller which is shown in the second image.

The “box” like impeller was concieved as an early attempt to prevent tip leakage losses.

The revised impeller, with fully shrouded form provided considerably improved performance.